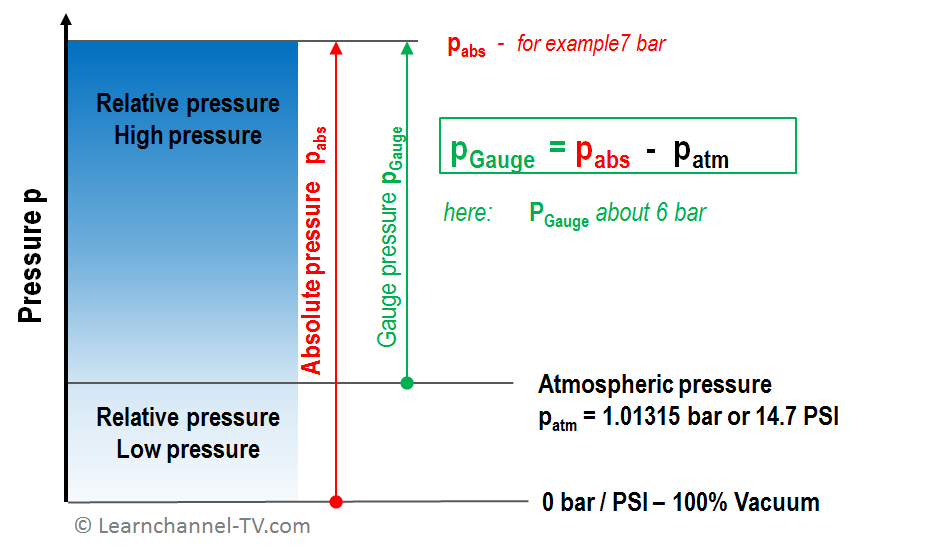

While it’s not as fun, easy, cheap, rewarding, or safe as using PVC pipe as a pressure vessel, the team did manage to build a 3D printed pressure vessel with a custom shape. Of course no 3D print is perfect, and the third prototype did leak, but a bit of acrylic spray paint applied to the outer surfaces held the air in. The third time’s the charm, and with filleted ribs inside the tank, the third prototype was able to hold pressure up to 6.5 bar.

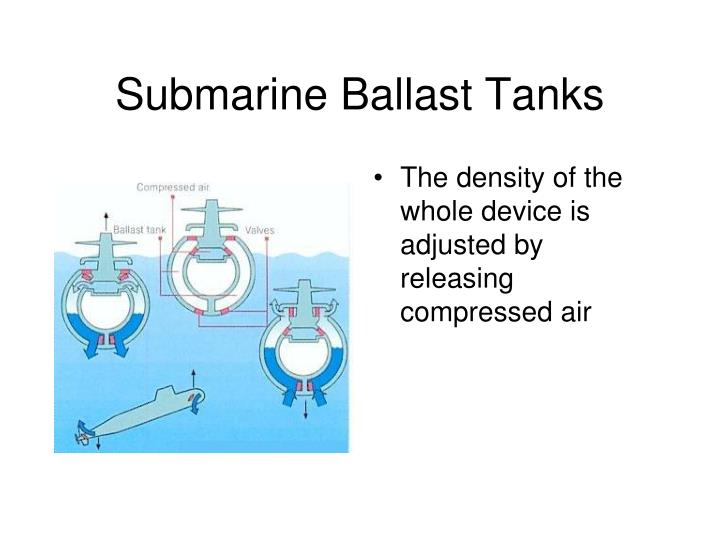

This success didn’t last, though: he second prototype, a 65x40x80mm rectangular prism printed without as much infill, exploded at 5.5bar (550kPa). The first prototype, a 40mm cube with 20% infill and a hole drilled in the side, held 6.5 bar (650kPa) for an hour. The tank for this robot would only be used up to about 4 bar (400kPa), and after a few quick calculations, the team discovered the wall thickness – even in a pressure vessel with corners – would be pretty low. Is it possible to 3D print a tank for compressed air? Since just about everything else on this robot is 3D printed, they asked the obvious question. That means compressed air, and that means a pressure vessel. A group of students in Renens, Switzerland are building autonomous robots for the Eurobot competition, and this year’s robot uses pneumatics. Compressed air stored in a PVC pipe is never a proximal cause in any accident, and the OSHA’s Fatality and Catastrophe Investigation Summaries bear this out there was no industrial or occupational accident recorded in these summaries where a pressure vessel made out of PVC was the cause of any injury or death.Īlthough PVC pipe can be a perfectly safe, effective, and cheap pressure vessel for hobby applications, it’s not always the best choice.

It’s safe, too: while there are are reports of PVC pipe being the cause of accidents, these accidents include a black powder potato gun, and welding too close to a PVC pipe containing compressed air. Using PVC pipe as a pressure vessel for compressed air can be a fun and enjoyable hobby.

0 kommentar(er)

0 kommentar(er)